UBCO researchers Farhad Ahmadijokani and Mohammad Arjmand have developed a cost-effective material that can help remove toxic chemicals, like cancer-treatment drugs, from water supplies.

UBCO researchers Farhad Ahmadijokani and Mohammad Arjmand have developed a cost-effective material that can help remove toxic chemicals, like cancer-treatment drugs, from water supplies.

Posted in Media Releases

A UBCO student project developed a method to make shipping containers immediately identifiable by using artificial intelligence.

With hundreds of thousands of packages and shipments crossing the globe, especially during the holiday season, the industry has turned to UBC Okanagan researchers to develop better ways to track parcels.

Marine shipping accounts for 20 per cent of all Canadian imports and exports, so there’s little wonder that the maritime transportation industry is keen on improving its tracking capabilities, says UBCO’s Zheng Liu.

Liu, a professor in the School of Engineering, says his team of student researchers are using deep learning algorithms, including cloud computing technology, to help create a monitoring software that can be used by shipping companies to track shipments more effectively.

“Deep learning works like the human brain by making smart conclusions with the information at hand,” explains Liu. “Our algorithm takes the shipping container code, even one that is not clearly legible, and is able to extract its information accurately.”

When shipped, containers use a common code that tells the monitoring software where the container is from and where it is going. The researchers were looking to improve existing methods—today’s systems locate the code on the container, and then quickly and accurately recognize the code.

By using a state-of-the art algorithm and advanced tracking hardware, the researchers were able to get the system to recognize the tracking information in less than a second. In comparison with the manual check and entry, the solution can greatly improve efficiency at the port.

In collaboration with CANSCAN, a company that uses artificial intelligence to secure shipping containers, the UBC student researchers have been developing tools for use at the Port of Montreal, which is an international container port that services Toronto and the rest of central Canada. The port tracks nearly two million containers annually—and these containers are currently being tracked with manual systems.

The student project, called Applying Machine Vision and Artificial Intelligence to Maritime Transportation, won top prize at the school’s capstone engineering contest last spring. The goal was to make the shipping containers immediately identifiable using artificial intelligence. This research will free up time for workers at the port who still input data manually.

“By digitizing the logistics of shipping containers, it helps to further improve shipping transportation to ultimately ensure that packages destined for our doorstep arrive on-time while being tracked from the sender to us,” says Liu.

The research, with funding from Mitacs, was published in the latest edition of the IEEE Xplore journal.

A UBCO student project developed a method to make shipping containers immediately identifiable by using artificial intelligence.

With hundreds of thousands of packages and shipments crossing the globe, especially during the holiday season, the industry has turned to UBC Okanagan researchers to develop better ways to track parcels.

Marine shipping accounts for 20 per cent of all Canadian imports and exports, so there’s little wonder that the maritime transportation industry is keen on improving its tracking capabilities, says UBCO’s Zheng Liu.

Liu, a professor in the School of Engineering, says his team of student researchers are using deep learning algorithms, including cloud computing technology, to help create a monitoring software that can be used by shipping companies to track shipments more effectively.

“Deep learning works like the human brain by making smart conclusions with the information at hand,” explains Liu. “Our algorithm takes the shipping container code, even one that is not clearly legible, and is able to extract its information accurately.”

When shipped, containers use a common code that tells the monitoring software where the container is from and where it is going. The researchers were looking to improve existing methods—today’s systems locate the code on the container, and then quickly and accurately recognize the code.

By using a state-of-the art algorithm and advanced tracking hardware, the researchers were able to get the system to recognize the tracking information in less than a second. In comparison with the manual check and entry, the solution can greatly improve efficiency at the port.

In collaboration with CANSCAN, a company that uses artificial intelligence to secure shipping containers, the UBC student researchers have been developing tools for use at the Port of Montreal, which is an international container port that services Toronto and the rest of central Canada. The port tracks nearly two million containers annually—and these containers are currently being tracked with manual systems.

The student project, called Applying Machine Vision and Artificial Intelligence to Maritime Transportation, won top prize at the school’s capstone engineering contest last spring. The goal was to make the shipping containers immediately identifiable using artificial intelligence. This research will free up time for workers at the port who still input data manually.

“By digitizing the logistics of shipping containers, it helps to further improve shipping transportation to ultimately ensure that packages destined for our doorstep arrive on-time while being tracked from the sender to us,” says Liu.

The research, with funding from Mitacs, was published in the latest edition of the IEEE Xplore journal.

Posted in College of Graduate Studies, Media Releases, Research

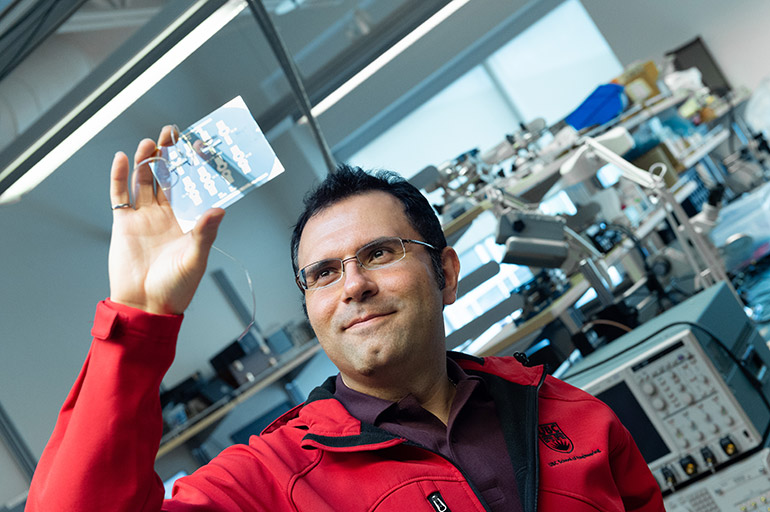

School of Engineering Mohammad Zarifi has made significant improvements to the real-time sensors that monitor frost and ice build-up on airplanes and turbines.

Posted in Media Releases

Photo caption: UBCO researchers Negin Kazemian and her supervisor, Assistant Professor Sepideh Pakpour, are investigating the internal dynamics of fecal matter donors and recipients to determine the effectiveness of the therapy.

Posted in Media Releases, Research

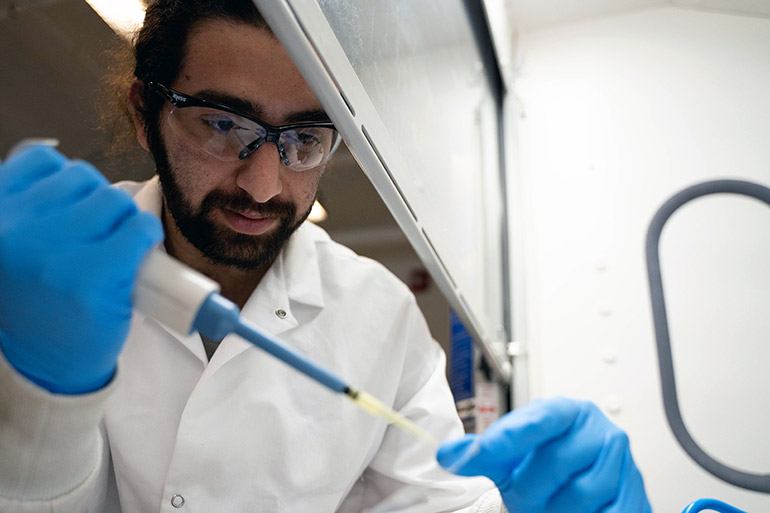

UBCO master's student Behrooz Khatir measures liquid to be applied to an omniphobic film during testing inside the OPERA lab at UBC Okanagan’s School of Engineering.

Posted in Media Releases, Research

UBC Associate Professor Sunny Li, right, discusses adaptations to the Airborne Infection Isolation and Removal system, with his doctoral student Mojtaba Zabihi and Care Health Meditech Managing Partner Stephen Munro, centre.

Posted in Business, Media Releases, Research

Rick Mercer will deliver the 2020 keynote address. Mercer was a 2010 UBC honorary degree recipient.

Posted in College of Graduate Studies, Media Releases

UBC Okanagan’s Rehan Sadiq, left, discusses drinking water assessment tools and benchmarking strategies with students Gyan K C Shrestha and Sarin Raj Pokhrel.

Posted in Media Releases

UBCO researchers are looking at creating new policy and planning tools to address flooding in the Okanagan Valley.

Posted in Media Releases

Chief Scientist at PRE Labs Mazeyar Parvinzadeh Gashti tests several different soap products on a protective face shield.

Posted in Business, Media Releases