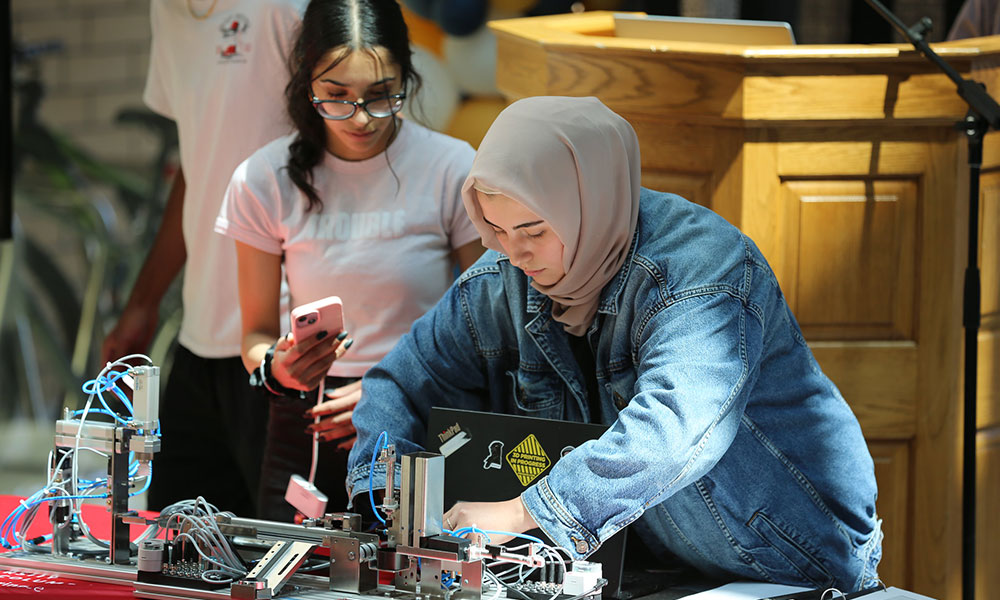

Dr. Mohamed Shehata and Dr. John Braun at UBC Okanagan recently received a Husky A300 Starter Kit through Clearpath Robotics’ 2024 PartnerBot Grant Program. The grant supports innovative robotics research by providing equipment and resources to Canadian institutions.

A new research initiative at UBC Okanagan is using robotics and artificial intelligence to address two of Canada’s biggest challenges: wildfire mitigation and sustainable agriculture.

Dr. Mohamed Shehata, Dr. John Braun and their UBC Okanagan student recently received a Husky A300 Starter Kit through the 2024 PartnerBot Grant Program.

“The Husky A300 allows us to develop and test our navigation algorithms in real conditions,” says Dr. Shehata, a Professor of Computer Science with the Irving K. Barber Faculty of Science. “It’s not just theoretical anymore—we can take it into the field, collect real data, and refine how these robots can work in challenging environments.”

Wildfire response: Reducing risk for firefighters

One of the most effective ways to control wildfires is to use a fire line, a cleared strip of land where vegetation is removed or burned down to bare mineral soil. This creates a barrier designed to stop or significantly slow the progression of a wildfire by depriving it of fuel to burn across.

Dr. Shehata’s team is exploring how autonomous robots, guided by AI and drone-assisted navigation, could perform these high-risk tasks. For example, the Husky A300 could be equipped with fire ignition tools or high-pressure water hoses, reducing the need for firefighters to enter high-risk areas.

Working alongside drones, which provide real-time data and mapping, the robot could navigate rough landscapes and assist in targeted fire suppression, making wildfire management safer and more precise.

“We’re looking at how we can send these robots into difficult terrain and control them remotely,” Dr. Shehata says. “Instead of putting firefighters at risk, we can use AI-powered navigation and real-time data visualization to guide operations from a safe distance.”

The team is collaborating with wildfire researchers at UBCO and an Alberta company specializing in high-pressure water delivery systems to explore how robots could complement existing aerial firefighting tools like helicopters.

Precision agriculture: Smarter, chemical-free farming

Beyond wildfires, Dr. Shehata is applying robotics to agriculture, using AI to help farmers detect weeds, monitor crop health and reduce chemical herbicides.

This automation can reduce chemical use, improve crop yields and make farming more sustainable—key priorities for Canada’s agricultural sector.

It’s the type of work made possible through engaged community partners such as the PartnerBot program. Established by Clearpath Robotics in 2012, the program supports innovative robotics projects by providing equipment and resources.

“We’re working with the Summerland Research and Development Centre and partners in Germany to develop new ways to use robotics in precision farming,” Dr. Shehata says. “Using AI and sensor-equipped drones, we can map fields and identify exactly where intervention is needed—whether it’s watering, fertilizing or targeted weed removal using lasers instead of herbicides.”

The post Robotics, AI advancing wildfire, agricultural research at UBCO appeared first on UBC's Okanagan News.