Manufacturing Engineering students are taking advantage of learning high-level production management skills in MANF 270. MANF270, Production Management course, provides students with hands-on opportunities to put lean manufacturing concepts related to increasing productivity into action.

“Obviously, this term has been a bit different as a result of the pandemic,” explains MANF 270 Lecturer Hassan Iqbal, “but it has enabled students to truly put these concepts into practice in their homes and at their workplaces.”

The focus of the course is learning, understanding, and implementing the Lean Manufacturing “Toyota Production System (TPS).” Dating back to the 1930s, TPS champions the concept of lean manufacturing where waste within a system is reduced to allow for optimal productivity.

Some students were able to take the concepts into real-world situations. Second-year Manufacturing student, Spencer Faubert, used the principles at his family’s vanilla extract company. “Already the people at work have told me what a great difference these small improvements have made to the day-to-day operations.”

“This project was a great chance to actually apply some of the concepts we were learning while studying from home,” says Aidan Mundle, a second year Manufacturing Engineering student. “We could physically implement it, we could see the results, and we can continue to work on it throughout the year. It was a personalized, beneficial, and useful project that I enjoyed.”

Using his home workshop as a lab, Mundle strategically organized tools and equipment to make everything more accessible and easier to find by implementing the 5-S lean tool.

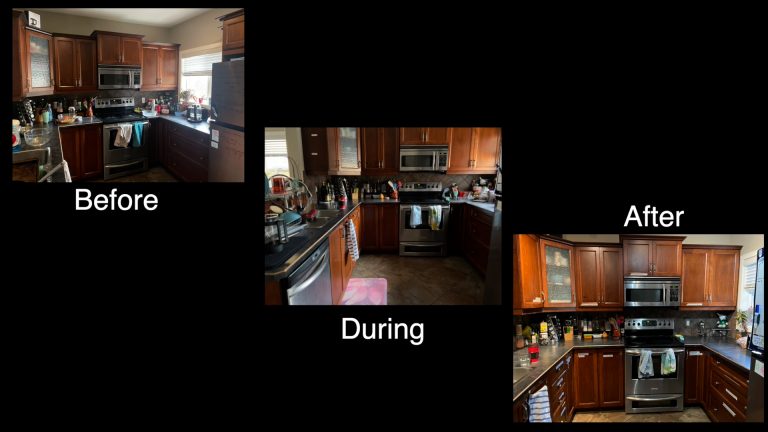

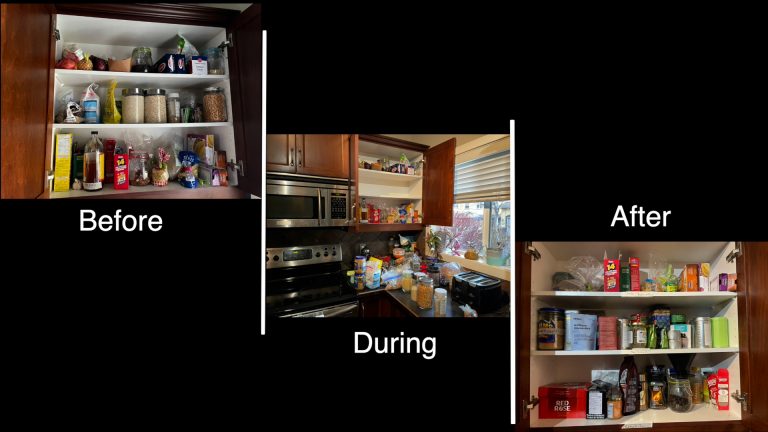

Vania Amadi, a second-year Manufacturing student, had a similar experience undertaking her course project. “These concepts are both useful and applicable that everyone should learn in order to increase efficiency all the way round.”

According to Iqbal, the students are all demonstrating a keen enthusiasm towards streamlining how they approach a task. “Students have been able to effectively identify the process wastes, and then adapt best practices to minimize/eliminate them. In fact during the pandemic, many of us have been taking a similar assessment of our homes and lives, and taking similar steps without realizing the connection to lean manufacturing.”

Students in MANF 270 not only learned about the building blocks of lean manufacturing but also implemented the Kaizen and 5S system, a visual management process intended to make workplaces more organized and efficient.

Manufacturing Engineering at UBC Okanagan’s School of Engineering encourages students to investigate the evolving world of manufacturing including additive manufacturing, advanced materials, adaptive robotics, artificial intelligence, autonomous systems, digitalization, factory planning, production management, modern manufacturing practices and Industry 4.0. For more information visit: https://engineering.ok.ubc.ca/programs-admissions/manufacturing/