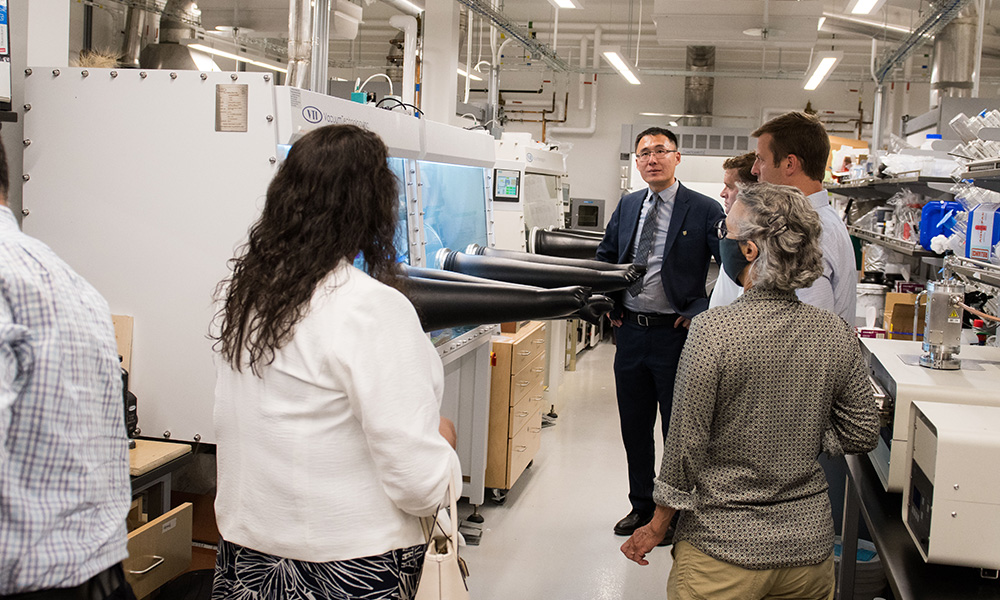

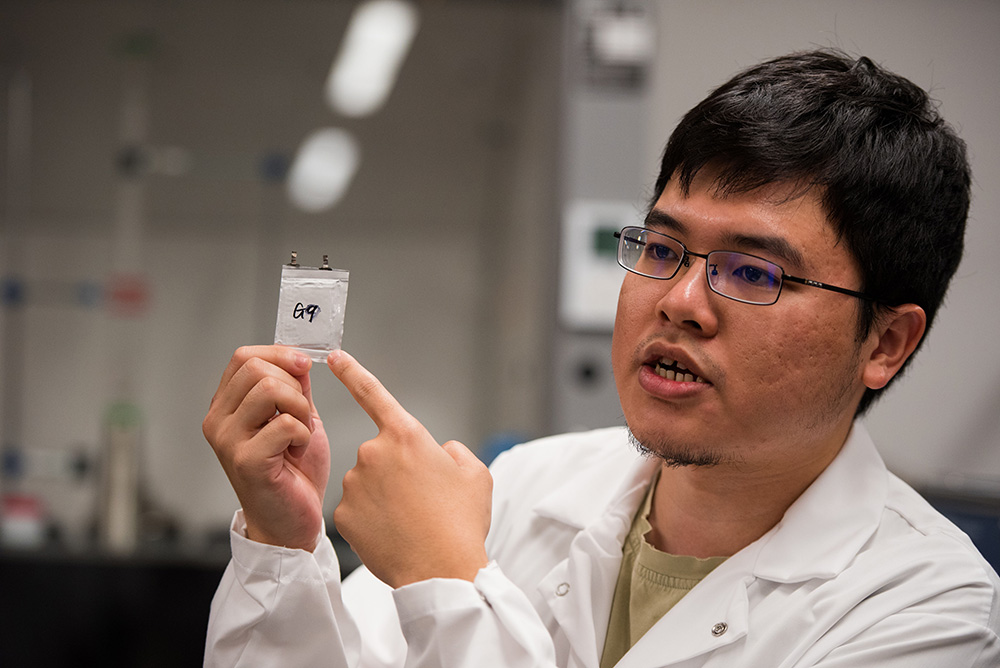

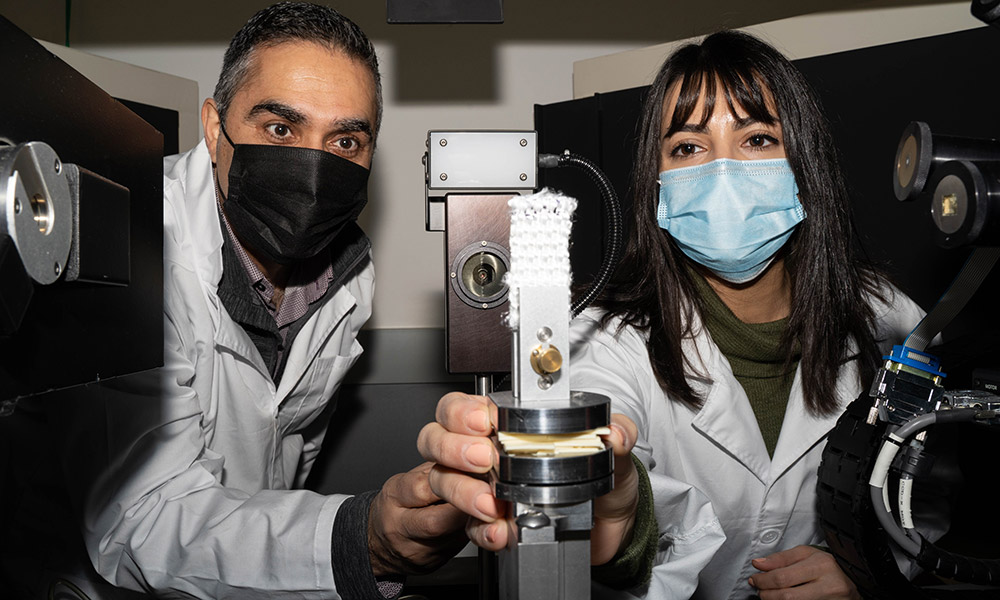

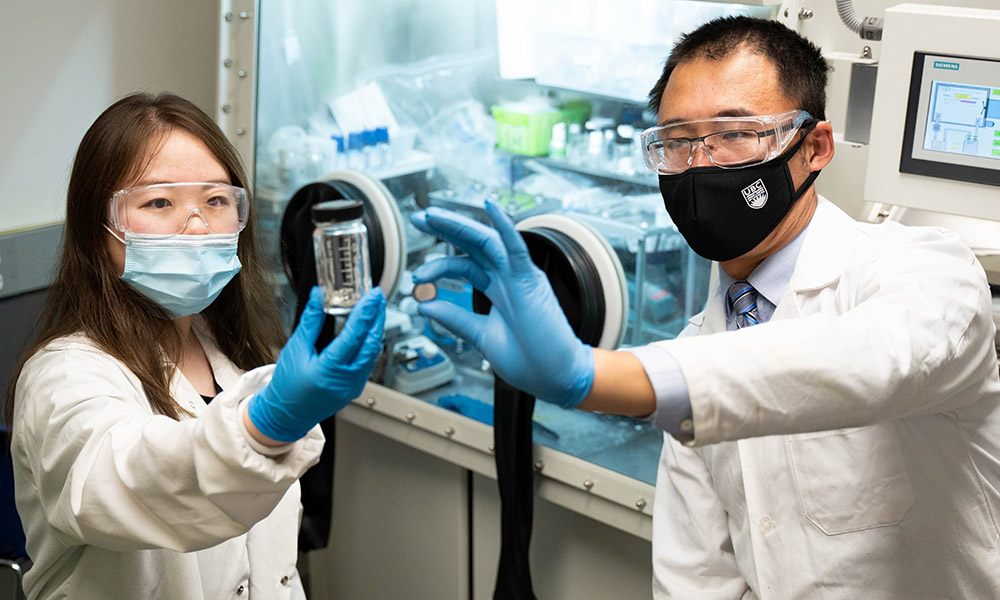

Connor Badowich and Pradeep Pugalendhi, both graduates of UBC Okanagan’s School of Engineering, at work at KF Aerospace in Kelowna.

To address the increasing demand for aerospace engineers in Western Canada, UBC Okanagan’s School of Engineering is launching an aerospace option.

The new option will be available to manufacturing and mechanical engineering students, explains Dr. Joshua Brinkerhoff, an Associate Professor of Mechanical Engineering and coordinator of the aerospace option.

“Aerospace is a huge industry in British Columbia, and across Western Canada,” he says. “Our industry partners in the aerospace sector are seeking highly-qualified graduates with very specific skills. This option will provide a solid foundation for our students to meet those requirements.”

Kelowna’s KF Aerospace has been a significant partner in helping to guide and develop the new program. KF Aerospace is the city’s largest private sector employer and currently has 25 engineering graduates.

“KF Aerospace is very excited to have an aerospace engineering option at UBC Okanagan. This program will help support us with locally grown talent as we continue to expand Canada’s leading engineering services,” says Gregg Evjen, KF Chief Operating Officer. “We thank UBCO for its support in launching a program that will help grow the aerospace sector in Western Canada.”

The aerospace engineering option will equip students with state-of-the-art skills, competencies, theories and design methodologies to train engineers with specialized skill sets in aerospace engineering.

“Our students have a track record of excellence in a variety of disciplines and we are excited to expand our offerings so they can continue to explore what they’re passionate about,” says Dr. Will Hughes, Director of the School of Engineering.

The first intake for the aerospace engineering option begins this fall and before completing the program students will be required to do a fourth-year aerospace capstone project.

“It is a big undertaking to establish a new option in aerospace engineering, but based on feedback from students, faculty and industry, we are confident in this program’s future horizon,” says Dr. Hughes. “We can’t wait to get it off the ground, and we are excited to introduce this new option to our students.”

To learn more about the opportunities available to students who chose this option, visit: engineering.ok.ubc.ca/2022/01/14/graduates-careers-take-flight-at-kf-aerospace

The post UBCO’s new aerospace option takes flight appeared first on UBC Okanagan News.